As a leader in the injection mold industry, Abtec Inc. professionals realize that every project is unique and oriented to the special requirements of our clients. In this regard, our staff of engineers, designers, and fabricators enjoy the challenge of custom injection molded designs that necessitate precision engineering. Since Abtec Inc. has equipment to meet the requirements of any injection molding design, we can take a client’s vision and convert it into a reality, regardless of how it is presented.

Continue reading “Custom Injection Molding”

Blog

Custom Injection Molding

Revolutionizing Manufacturing with Custom Thermoplastic Injection Molding

Custom Thermoplastic Injection Molding Part Design with Abtec Inc.

In today’s fast-paced world, businesses thrive on innovation and efficiency. One company leading this charge is Abtec Inc., specializing in custom thermoplastic injection molding. We are not just another manufacturing firm; we are your strategic partner in bringing your unique designs to life with precision and speed.

Continue reading “Revolutionizing Manufacturing with Custom Thermoplastic Injection Molding”

Plastic Injection Molding Innovation & Creativity

Fostering Innovation and Creativity with Custom Thermoplastic Injection Molding from Abtec Inc.

In today’s rapidly evolving manufacturing landscape, innovation and creativity are critical elements for companies striving to stay competitive. One often overlooked avenue for achieving this is through thermoplastic injection molding. Abtec Inc., a renowned plastic injection molding company, has been at the forefront of fostering innovation and creativity in various industries. In this article, we will explore how plastic injection molding from Abtec Inc can drive forward-thinking solutions and inspire new possibilities.

Continue reading “Plastic Injection Molding Innovation & Creativity”

The Power of Turnkey Automation at Abtec Inc.

In today’s rapidly evolving industrial landscape, the demand for efficiency, precision, and scalability has never been higher. With industries facing shortages in both skilled and unskilled labor, innovative solutions are essential to maintain competitiveness and meet customer demands. Abtec Inc., a pioneering thermoplastic injection molding company established in April 1981, has emerged as a beacon of excellence in this challenging terrain, thanks to its groundbreaking turnkey automation systems.

As the manufacturing sector grapples with the ongoing labor shortage, Abtec Inc. has been at the forefront of leveraging automation to revolutionize its operations. Specializing in custom molded products, Abtec has seamlessly integrated state-of-the-art automation technologies into its production processes, ensuring unparalleled efficiency, consistency, and reliability.

One of the key advantages of Abtec’s turnkey automation solutions is their ability to mitigate the impact of labor shortages. By automating repetitive tasks and streamlining workflows, Abtec Inc. has significantly reduced its reliance on manual labor while enhancing productivity and output. This not only addresses the challenges posed by the current labor market but also positions Abtec Inc. as a trailblazer in delivering superior quality products with shorter lead times.

Continue reading “The Power of Turnkey Automation at Abtec Inc.”

Revolutionizing Industry Standards: Abtec’s Impact on Custom Thermoplastic Bobbins for OEMs

In the world of manufacturing, precision and customization are key factors that can make or break a company’s success. One such company that has been leading the charge in this space is dedicated to crafting custom thermoplastic bobbins, Abtec Inc.

Let’s delve into how Abtec’s competitive tooling and part prices have become a game-changer for Original Equipment Manufacturers (OEMs) seeking tailored solutions.

Custom Potting Shells

In today’s dynamic manufacturing landscape, the need for reliable and custom product solutions is more significant than ever. Abtec Inc. stands as a beacon of excellence in the realm of injection molding for custom potting shells. With a commitment to innovation, precision, and customer satisfaction, Abtec Inc. has earned its reputation as a leading full-service custom injection molding company.

Continue reading “Custom Potting Shells”

What to Look for When Partnering with an Injection Molding Company

At Abtec Inc., our team has over 100 years of combined experience serving as a global manufacturing partner for custom injection molding services. Utilizing advanced technologies such as computer-aided designs (CAD), we can rapidly produce precision injection molds and parts in a variety of engineer-grade resins. Our design, development, and manufacturing expertise equip us to help you address your production concerns at the best price.

Continue reading “What to Look for When Partnering with an Injection Molding Company”

Cost-effective Injection Molding for Medical Device Companies

In the ever-evolving landscape of medical device manufacturing, the demand for precision-engineered components has surged to unprecedented levels. Injection molded parts have emerged as a linchpin in this domain, serving as the backbone of intricate medical devices that require exceptional performance, reliability, and compliance. As the medical industry races to innovate and deliver cutting-edge solutions, Abtec Inc. stands as a beacon of expertise, poised to assist medical device companies in economically navigating the complex journey to market entry.

Continue reading “Cost-effective Injection Molding for Medical Device Companies”

Fiber Reinforced Resin in Thermoplastic Injection Molding

Fiber reinforced resins, also known as engineering grade resins, such as Acetal, PEEK, and Nylon, are increasingly gaining popularity in the continuously evolving realm of manufacturing.

Within thermoplastic injection molding, Abtec Inc. uses engineering-grade resins that are carving out a prominent niche poised to shape the industry’s future in profound ways.

Let’s delve into the anticipated trends that define the role of engineering grade resins in this sector.

Continue reading “Fiber Reinforced Resin in Thermoplastic Injection Molding”

Dealing Directly With a Manufacturer Like Abtec Inc. For Plastic Molded Parts and Tooling Instead of Using a Broker or Middleman Offers Several Advantages:

- Cost Efficiency: Eliminating intermediaries often leads to cost savings. When you work directly with the manufacturer, you avoid paying commissions or fees to the middleman, making your tooling and parts more affordable.

Using Custom Thermoplastic Injection Molds to Save Costs

In times of economic uncertainty, businesses are continually seeking innovative ways to cut costs and streamline operations. One potent avenue that has gained prominence is the adoption of custom thermoplastic injection molding. This process provides a compelling solution for companies grappling with expensive non-plastic parts and components procurement. By harnessing the capabilities of thermoplastic injection molding, businesses can not only weather the storm of a recession but also emerge stronger and more resilient.

Continue reading “Using Custom Thermoplastic Injection Molds to Save Costs”

The Impact of Insert Molding on Design, Performance, and Aesthetics

In the world of custom injection molding, Abtec’s insert molding has emerged as a groundbreaking technique that propels product design, performance, and aesthetics to new heights. This advanced process involves the integration of pre-fabricated components into the molding process, opening a realm of possibilities for innovation and enhancement. In this article, we delve into the profound impact of insert molding and how it brings together form, function, and aesthetics in a harmonious synthesis.

Continue reading “The Impact of Insert Molding on Design, Performance, and Aesthetics”

How Abtec Supports OEMs With Their Custom Injection Molding Needs

Original equipment manufacturers (OEMs) must strike a balance between quality, performance, and cost to consistently deliver on product commitments without jeopardizing their reputation and growth. It also requires them to create and maintain their supply chain with intention. Consequently, they must partner with suppliers who have demonstrated proficiency across various requirements.

Continue reading “How Abtec Supports OEMs With Their Custom Injection Molding Needs”

Quick Turnaround Tooling Isn’t Always the Answer

Well-engineered, precision tooling is the key to quality molded parts. Quick turnaround tooling may get the job done fast and be affordable, but getting it done right is more important in industries that require precision. Investing in tooling services engineered to perfection ensures high-quality molded parts for your manufacturing requirements. Thus, you need state-of-the-art tooling services with an uncompromised commitment to quality and customer satisfaction.

Continue reading “Quick Turnaround Tooling Isn’t Always the Answer”

Most Common Injection Molding Problems

Injection molding is the most versatile method for mass-producing identical components, and this is done by injecting molten plastic resin into a mold. It can be performed using various thermoplastics.

Despite its many benefits, such as fast production speed, high efficiency, operation automation, and shape and size flexibility, some issues and defects may arise during this process. This article will explain typical injection-molding problems. You’ll understand where problems usually come from and how Abtec Inc. can prevent these issues early via your part and tooling design and via our efficient manufacturing process.

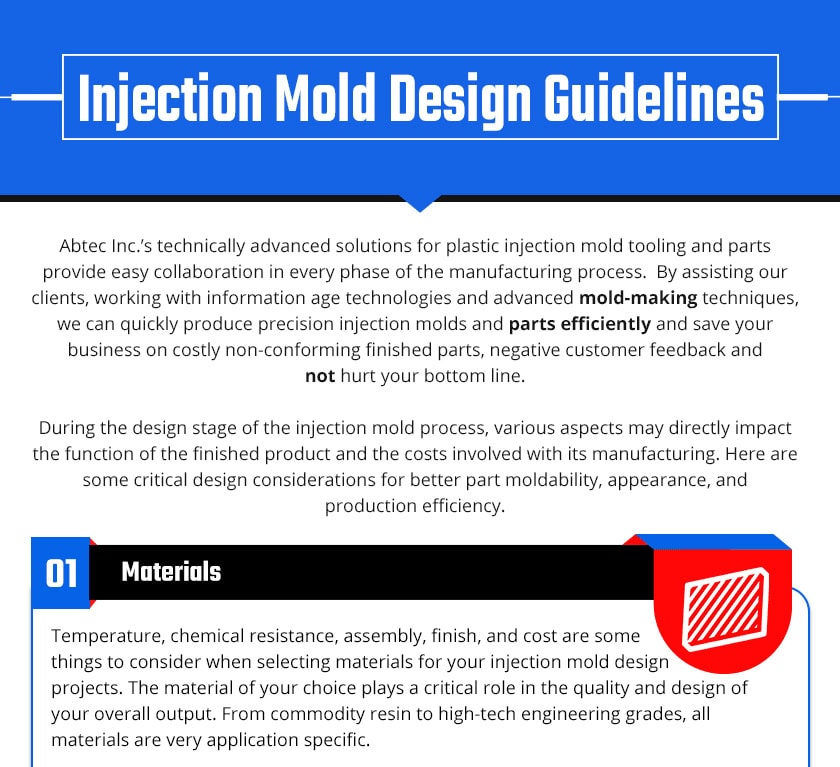

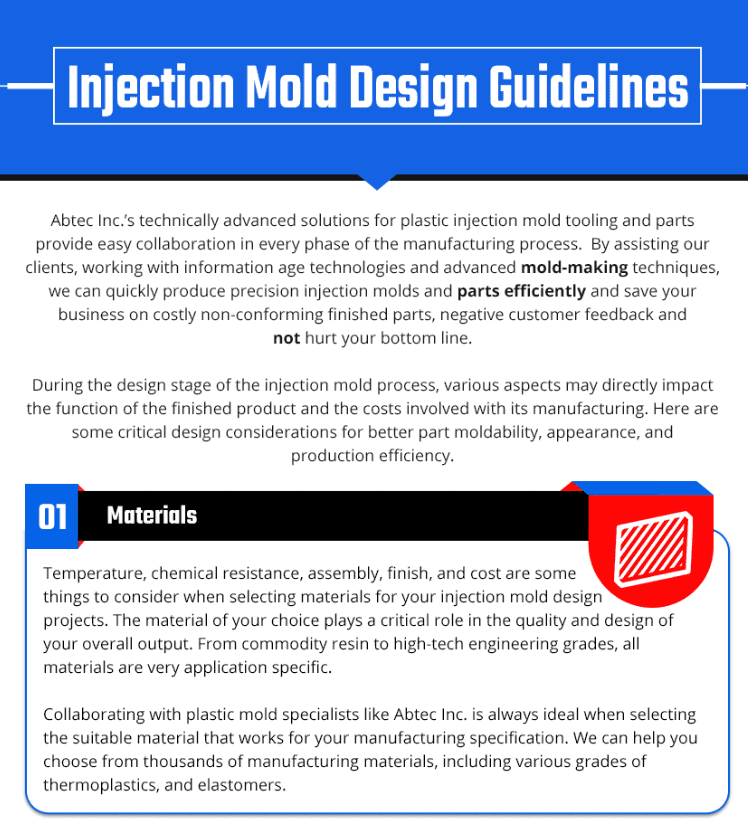

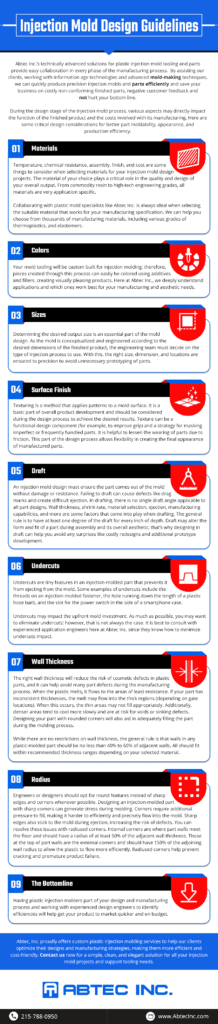

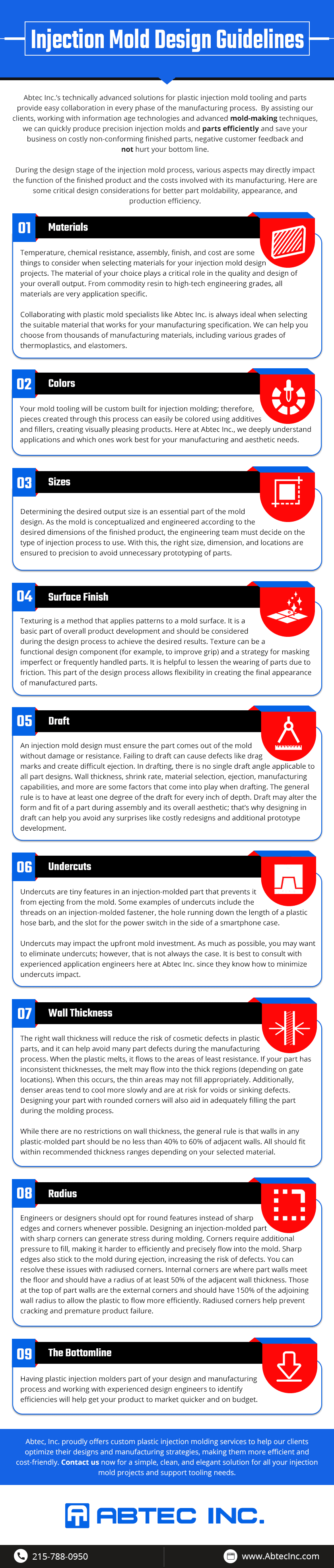

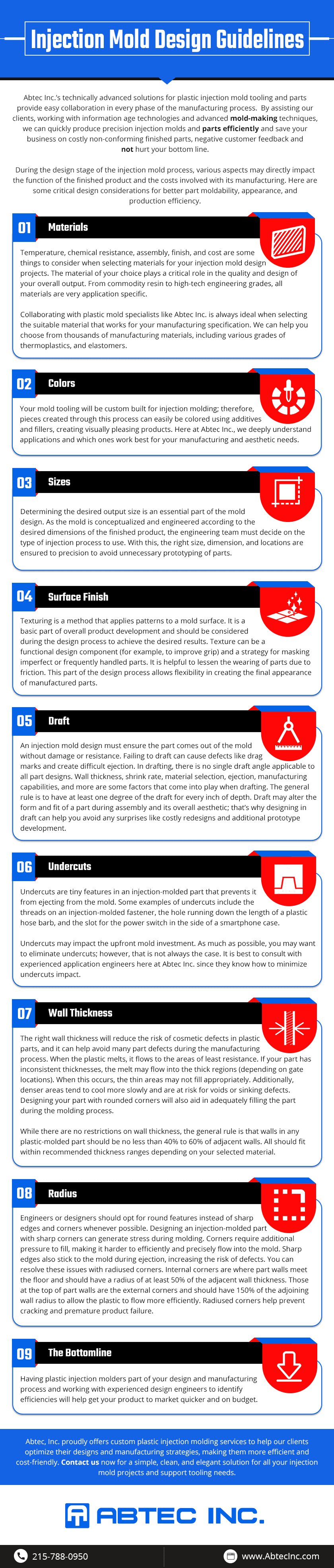

Injection Mold Design Guidelines

In the manufacturing industry, two critical factors are involved: quickly getting the products to market and ensuring they are within the budget. The design for the manufacturing process specified by the product manufacturers is the most critical part that can substantially impact production outcomes. Therefore, it is more time and cost-efficient when injection molders are involved early in the design part of this process.

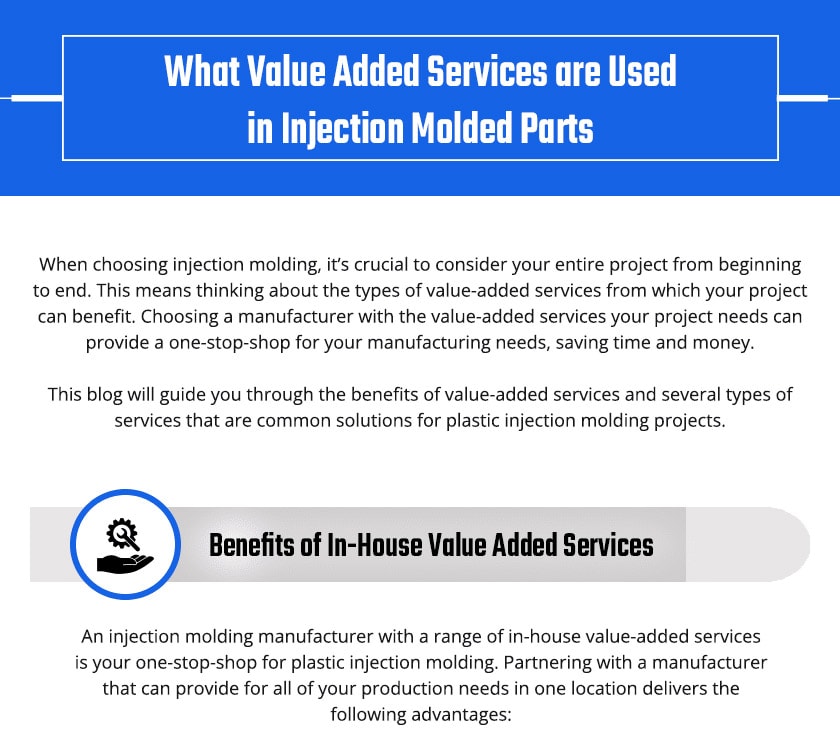

What Value-Added Services Are Used In Injection Molded Parts?

When choosing injection molding, it’s crucial to consider your entire project from beginning to end. This means thinking about the types of value-added services from which your project can benefit. Choosing a manufacturer with the value-added services your project needs can provide a one-stop-shop for your manufacturing needs, saving time and money.

Continue reading “What Value-Added Services Are Used In Injection Molded Parts?”

Proper Tooling & Injection Mold Maintenance at Abtec

Abtec has been providing custom injection molds and supporting tooling for various industries worldwide for more than 40 years. As a trusted global partner, we leverage cutting-edge technologies and advanced mold-making processes to produce precision injection molds within the shortest period of time. We also offer preventive mold maintenance solutions to guarantee the optimal performance of your molds and tools.

Continue reading “Proper Tooling & Injection Mold Maintenance at Abtec”

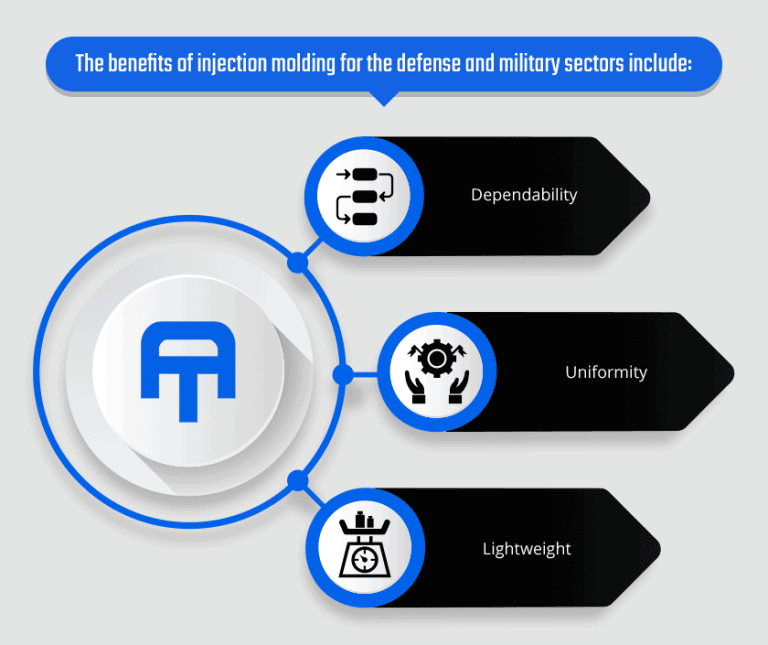

The Facts About Defense & Military Injection Molding

With more than a century of combined experience, Abtec Inc. provides quality plastic injection molding services to an array of industries. Our customers look to our parts to solve any number of production and manufacturing problems. They count on the versatility and efficiency of our equipment and team to fulfill a range of requests with quick turnaround times. Our expertise makes us well suited to deliver quality injection molded parts that meet the demanding standards of the defense and military sectors.

Continue reading “The Facts About Defense & Military Injection Molding”

Low-Volume or Short Run Injection Molding Solutions at Abtec

The process of bringing a new product to market involves many steps, including designing the component and creating prototypes to test out the design. After the design is finalized and the prototypes are evaluated, you may also want to produce a small number of pieces for internal or external product testing purposes before proceeding to full production. In the case of injection-molded components, one option for producing these pieces is short run injection molding—also known as small-volume, low-volume, or small-batch production. This production solution enables you to generate a limited batch that you can use to gauge market reaction so you can appropriately scale production to meet actual consumer demand.

Continue reading “Low-Volume or Short Run Injection Molding Solutions at Abtec”

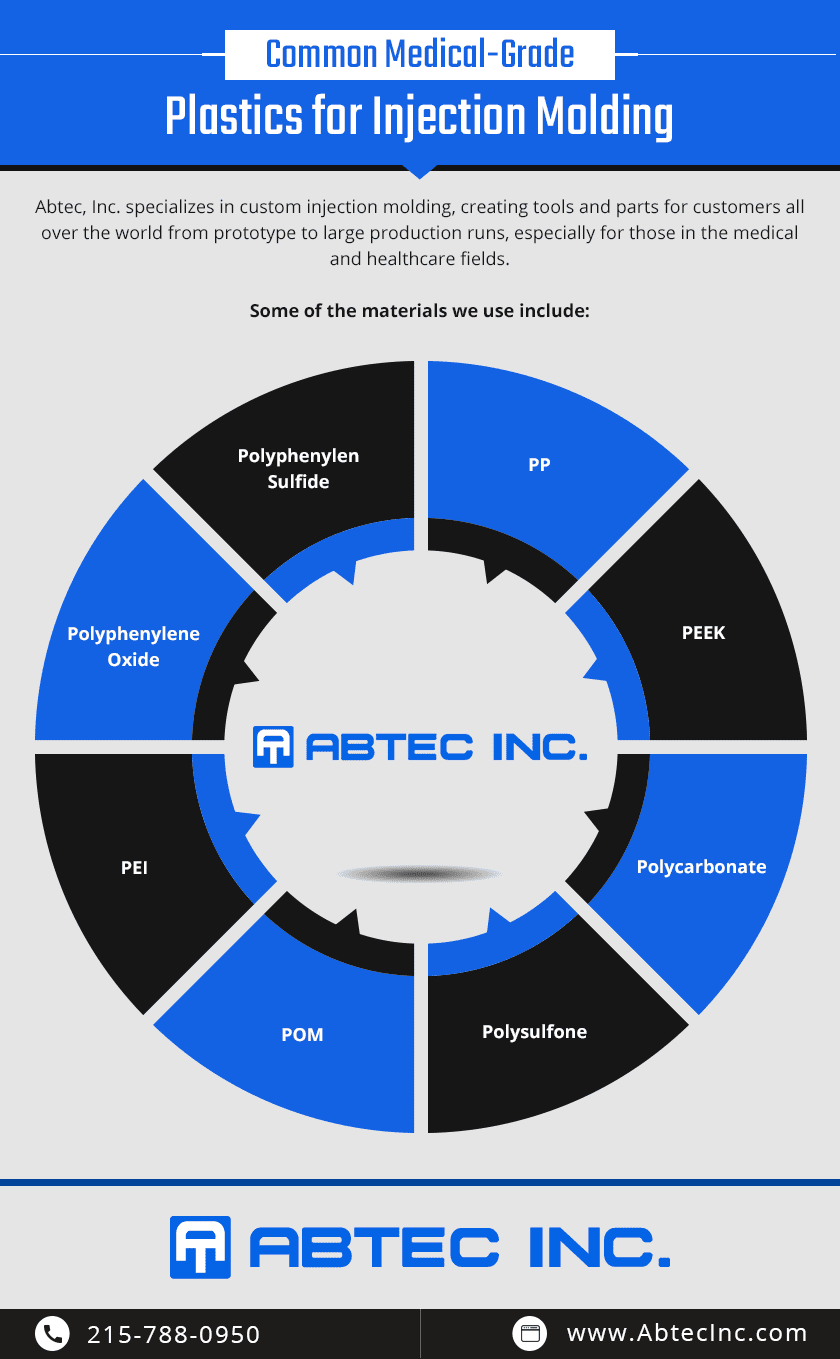

Plastic Injection Molding for the Medical Industry

At Abtec, Inc., we specialize in custom injection molding, creating tools and parts for customers all over the world from prototype to large production runs. Plastic injection molding is a manufacturing process that involves injecting liquified plastic into a mold, allowing it to conform to the shape of the mold and harden to create a specific shape. This beneficial process has numerous applications in many industries, including the medical industry.

Continue reading “Plastic Injection Molding for the Medical Industry”

Is 3D Printing Better Than Injection Molding?

Advanced technology gives companies more options when it comes to producing plastic components. Plastic injection molding and 3D printing are two of those options, and they both have their advantages, depending upon the application. While 3D printing is relatively new and attention-grabbing, plastic injection molding is still a trusted solution for precision manufacturing.

Continue reading “Is 3D Printing Better Than Injection Molding?”

The Materials Used for Our Custom Injection Molds

Abtec has a team of experts who design, develop, and manufacture custom injection molds and support tooling. When designing parts for injection molding, we work with the most advanced technologies and processes, including state-of-the-art 3D design software to produce precise injection molds and CNC machining technologies to manufacture quality molds in a short time frame.

Continue reading “The Materials Used for Our Custom Injection Molds”

What Can We Mold from ABS Plastic?

The Basics of ABS

Acrylonitrile butadiene styrene (ABS) is one of the most widely used thermoplastic polymers across numerous domestic, commercial, and industrial applications today. The history of ABS can be traced back to the 1940s. During this time, manufacturers often used styrene acrylonitrile copolymers. While this material’s increased hardness over styrene made it suitable for some applications, it still possessed many physical and mechanical limitations. This led to the introduction of a third monomer, butadiene, and acrylonitrile butadiene styrene (ABS) was created. This material was first available in the 1950s and has gone on to become one of the most widely sought engineering polymers.

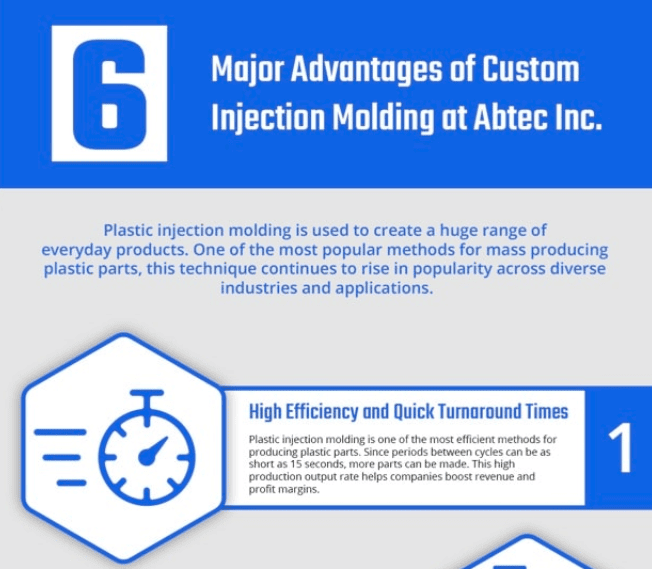

Custom Injection Molding Advantages at Abtec Inc.

At Abtec Inc., we’re proud to offer custom mold making services, helping clients bring their product visions to life. Versatile and reliable, plastic injection molding is used to create a huge range of everyday products. One of the most popular methods for mass producing plastic parts, this technique continues to rise in popularity across diverse industries and applications. Some of plastic injection molding advantages include the following:

Continue reading “Custom Injection Molding Advantages at Abtec Inc.”

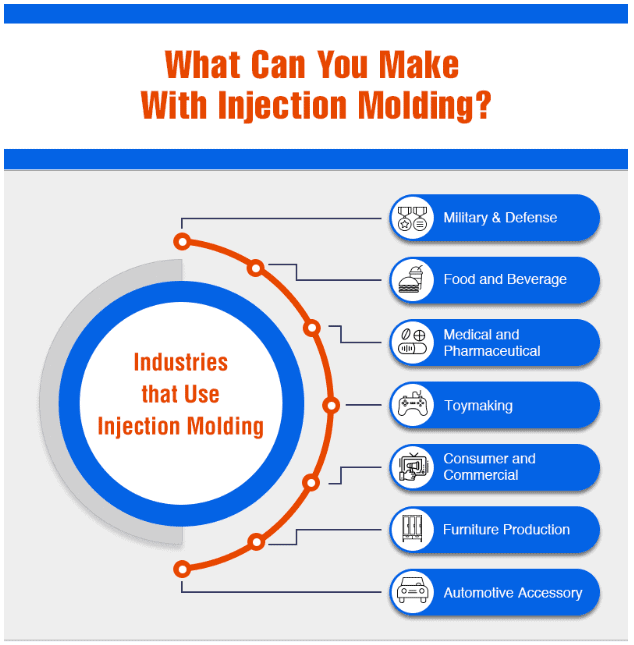

INFOGRAPHIC: What Can You Make with Injection Molding?

What can you make with injection molding? Scroll down to view our infographic!

Abtec, Inc provides injection molding services for a variety of materials and for a number of industries. Contact us today to find out how we can help with your next project!

Continue reading “INFOGRAPHIC: What Can You Make with Injection Molding?”

A Guide to Our Engineering Resins

Engineering resins are one of two types of plastics commonly used in the injection molding process. Commodity resins (the other common type) are inexpensive and typically used in consumer products like toys, packaging, and food containers. Engineering resins are ideal for use in industrial applications because they are strong and highly resistant to temperature, corrosion, and wear. Engineering resins also have special thermal and mechanical properties that make them useful in replacing wood and metal to save on costs and/or weight.

All You Need to Know About Injection Molded Thermoplastics

There are instances in manufacturing where metals cannot meet the weight and deflection demands specified by the application. When this is the case, thermoplastics often provide a solution. Thermoplastics are among a group of materials that melt when heated. They are common in manufacturing because heating makes them viscous, allowing for the formation of specific shapes which the material retains after cooling.

Continue reading “All You Need to Know About Injection Molded Thermoplastics”

INFOGRAPHIC: The Advantages of Plastic Injection Molding

Abtec, Inc. offers injection molding services for custom molds based on your design. We have a broad catalog of materials and thermoplastics, plus years of expertise to help get the job done right!

Continue reading “INFOGRAPHIC: The Advantages of Plastic Injection Molding”

Our Custom Thermoplastics Include Liquid Crystal Polymers for Your Design

Abtec’s custom injection molding services work with a wide variety of materials that range from commodity resins to high-tech, engineering-grade polymers. We work with the latest equipment and technology to design high-quality molds that create intricate and durable end products.

Continue reading “Our Custom Thermoplastics Include Liquid Crystal Polymers for Your Design”

The Properties of Polyetherimide (PEI)

What are some of the properties of polyetherimide (PEI)? Watch this informative video on why polyetherimide is a preferred thermoplastic for molding and design. Its versatility is excellent across a range of industries!

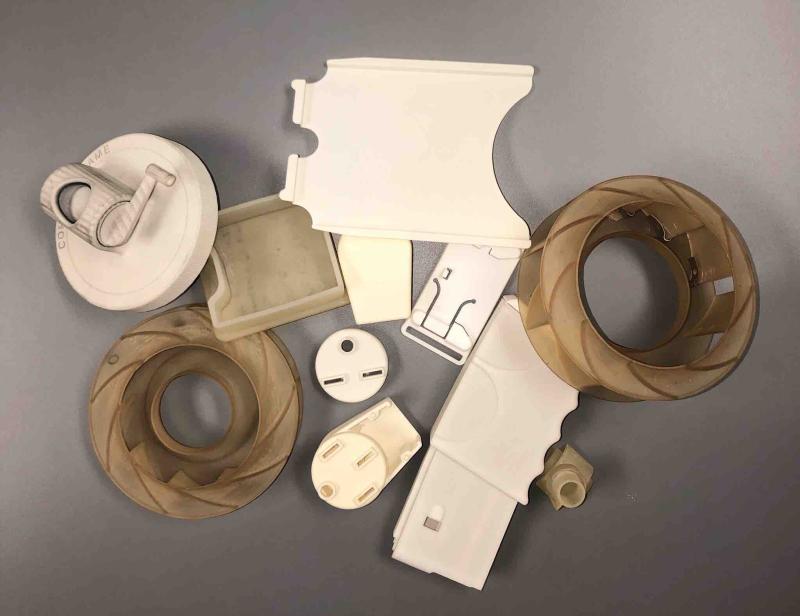

The Parts, Pieces, and Products Made From Custom Injection Molding

One of the biggest problems associated with creating or building materials is that sometimes, standard parts don’t fit your specific application. Sometimes, the tools you need to create these parts don’t even exist.

Continue reading “The Parts, Pieces, and Products Made From Custom Injection Molding”

Welcome to the blog for Abtec, Inc.!

Check back frequently for news, updates, company announcements, and more!