When choosing injection molding, it’s crucial to consider your entire project from beginning to end. This means thinking about the types of value-added services from which your project can benefit. Choosing a manufacturer with the value-added services your project needs can provide a one-stop-shop for your manufacturing needs, saving time and money.

This blog will guide you through the benefits of value-added services and several types of services that are common solutions for plastic injection molding projects.

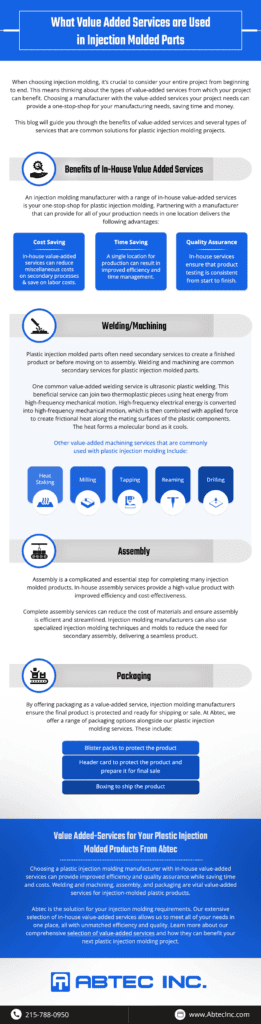

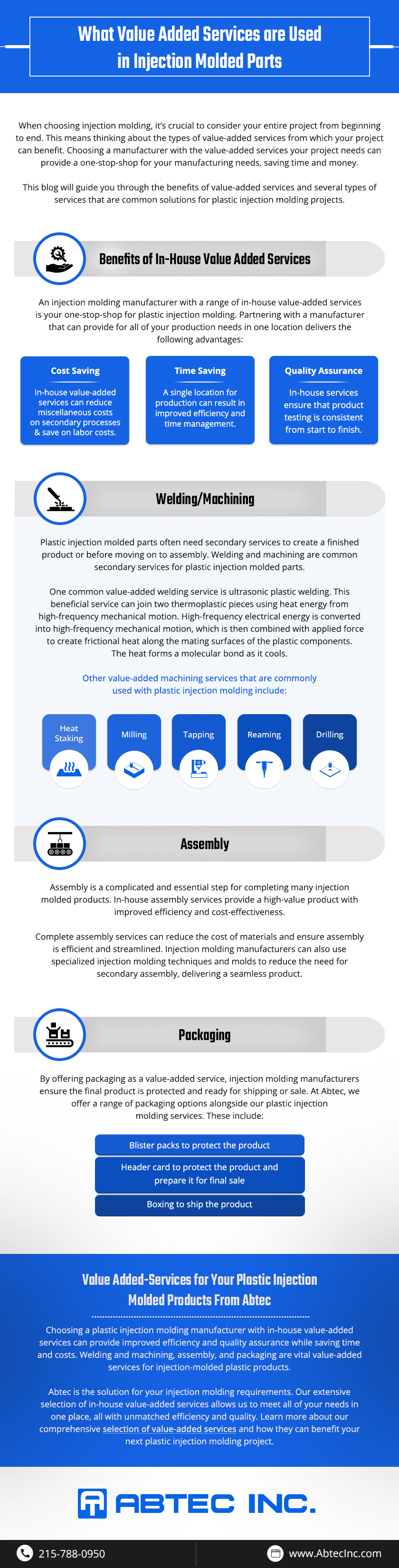

Benefits of In-House Value Added Services

An injection molding manufacturer with a range of in-house value-added services is your one-stop-shop for plastic injection molding. Partnering with a manufacturer that can provide for all of your production needs in one location delivers the following advantages:

- Cost Saving. In-house value-added services can reduce miscellaneous costs on secondary processes and save on labor costs.

- Time-Saving. A single location for production can result in improved efficiency and time management.

- Quality Assurance. In-house services ensure that product testing is consistent from start to finish.

Welding/Machining

Plastic injection molded parts often need secondary services to create a finished product or before moving on to assembly. Welding and machining are common secondary services for plastic injection molded parts.

One common value-added welding service is ultrasonic plastic welding. This beneficial service can join two thermoplastic pieces using heat energy from high-frequency mechanical motion. High-frequency electrical energy is converted into high-frequency mechanical motion, which is then combined with applied force to create frictional heat along the mating surfaces of the plastic components. The heat forms a molecular bond as it cools.

Other value-added machining services that are commonly used with plastic injection molding include:

- Heat staking

- Milling

- Tapping

- Reaming

- Drilling

Assembly

Assembly is a complicated and essential step for completing many injection molded products. In-house assembly services provide a high-value product with improved efficiency and cost-effectiveness.

Complete assembly services can reduce the cost of materials and ensure assembly is efficient and streamlined. Injection molding manufacturers can also use specialized injection molding techniques and molds to reduce the need for secondary assembly, delivering a seamless product.

Packaging

By offering packaging as a value-added service, injection molding manufacturers ensure the final product is protected and ready for shipping or sale. At Abtec, we offer a range of packaging options alongside our plastic injection molding services. These include:

- Blister packs to protect the product

- Header card to protect the product and prepare it for final sale

- Boxing to ship the product

Value Added-Services for Your Plastic Injection Molded Products From Abtec

Choosing a plastic injection molding manufacturer with in-house value-added services can provide improved efficiency and quality assurance while saving time and costs. Welding and machining, assembly, and packaging are vital value-added services for injection-molded plastic products.

Abtec is the solution for your injection molding requirements. Our extensive selection of in-house value-added services allows us to meet all of your needs in one place, all with unmatched efficiency and quality. Learn more about our comprehensive selection of value-added services and how they can benefit your next plastic injection molding project.