As a leader in the injection mold industry, Abtec Inc. professionals realize that every project is unique and oriented to the special requirements of our clients. In this regard, our staff of engineers, designers, and fabricators enjoy the challenge of custom injection molded designs that necessitate precision engineering. Since Abtec Inc. has equipment to meet the requirements of any injection molding design, we can take a client’s vision and convert it into a reality, regardless of how it is presented.

Continue reading “Custom Injection Molding”

Category: News

Revolutionizing Manufacturing with Custom Thermoplastic Injection Molding

Custom Thermoplastic Injection Molding Part Design with Abtec Inc.

In today’s fast-paced world, businesses thrive on innovation and efficiency. One company leading this charge is Abtec Inc., specializing in custom thermoplastic injection molding. We are not just another manufacturing firm; we are your strategic partner in bringing your unique designs to life with precision and speed.

Continue reading “Revolutionizing Manufacturing with Custom Thermoplastic Injection Molding”

Plastic Injection Molding Innovation & Creativity

Fostering Innovation and Creativity with Custom Thermoplastic Injection Molding from Abtec Inc.

In today’s rapidly evolving manufacturing landscape, innovation and creativity are critical elements for companies striving to stay competitive. One often overlooked avenue for achieving this is through thermoplastic injection molding. Abtec Inc., a renowned plastic injection molding company, has been at the forefront of fostering innovation and creativity in various industries. In this article, we will explore how plastic injection molding from Abtec Inc can drive forward-thinking solutions and inspire new possibilities.

Continue reading “Plastic Injection Molding Innovation & Creativity”

The Power of Turnkey Automation at Abtec Inc.

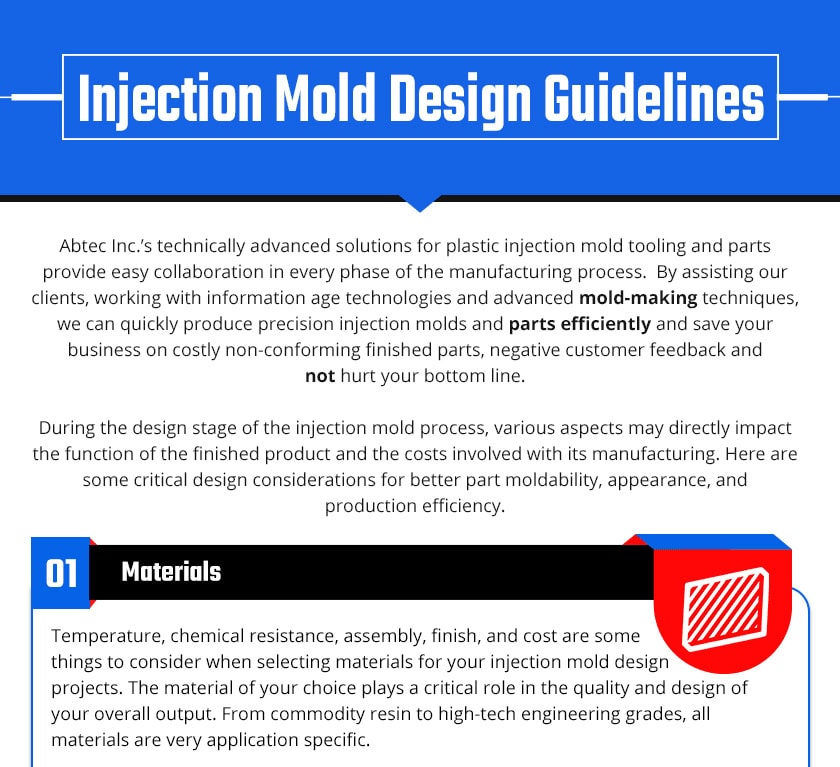

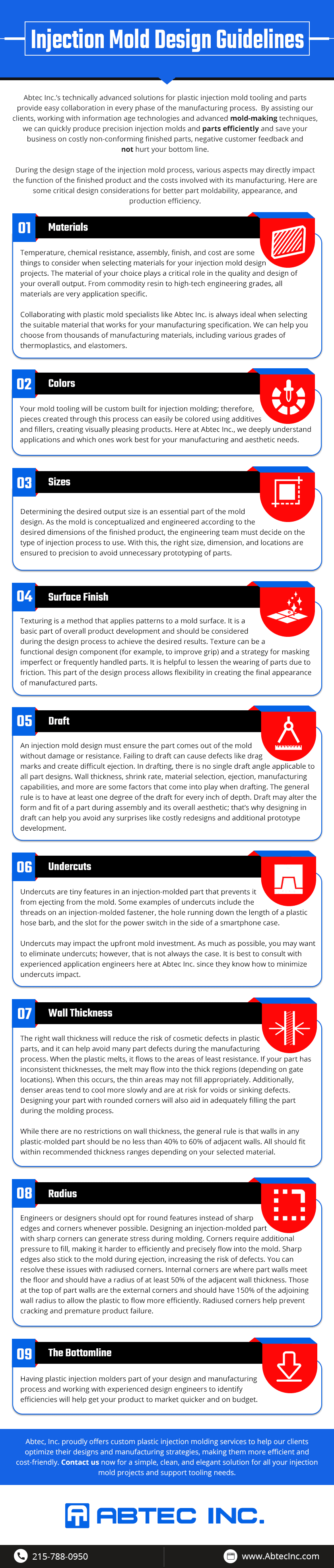

In today’s rapidly evolving industrial landscape, the demand for efficiency, precision, and scalability has never been higher. With industries facing shortages in both skilled and unskilled labor, innovative solutions are essential to maintain competitiveness and meet customer demands. Abtec Inc., a pioneering thermoplastic injection molding company established in April 1981, has emerged as a beacon of excellence in this challenging terrain, thanks to its groundbreaking turnkey automation systems.

As the manufacturing sector grapples with the ongoing labor shortage, Abtec Inc. has been at the forefront of leveraging automation to revolutionize its operations. Specializing in custom molded products, Abtec has seamlessly integrated state-of-the-art automation technologies into its production processes, ensuring unparalleled efficiency, consistency, and reliability.

One of the key advantages of Abtec’s turnkey automation solutions is their ability to mitigate the impact of labor shortages. By automating repetitive tasks and streamlining workflows, Abtec Inc. has significantly reduced its reliance on manual labor while enhancing productivity and output. This not only addresses the challenges posed by the current labor market but also positions Abtec Inc. as a trailblazer in delivering superior quality products with shorter lead times.

Continue reading “The Power of Turnkey Automation at Abtec Inc.”

Dealing Directly With a Manufacturer Like Abtec Inc. For Plastic Molded Parts and Tooling Instead of Using a Broker or Middleman Offers Several Advantages:

- Cost Efficiency: Eliminating intermediaries often leads to cost savings. When you work directly with the manufacturer, you avoid paying commissions or fees to the middleman, making your tooling and parts more affordable.

Using Custom Thermoplastic Injection Molds to Save Costs

In times of economic uncertainty, businesses are continually seeking innovative ways to cut costs and streamline operations. One potent avenue that has gained prominence is the adoption of custom thermoplastic injection molding. This process provides a compelling solution for companies grappling with expensive non-plastic parts and components procurement. By harnessing the capabilities of thermoplastic injection molding, businesses can not only weather the storm of a recession but also emerge stronger and more resilient.

Continue reading “Using Custom Thermoplastic Injection Molds to Save Costs”

The Impact of Insert Molding on Design, Performance, and Aesthetics

In the world of custom injection molding, Abtec’s insert molding has emerged as a groundbreaking technique that propels product design, performance, and aesthetics to new heights. This advanced process involves the integration of pre-fabricated components into the molding process, opening a realm of possibilities for innovation and enhancement. In this article, we delve into the profound impact of insert molding and how it brings together form, function, and aesthetics in a harmonious synthesis.

Continue reading “The Impact of Insert Molding on Design, Performance, and Aesthetics”

Welcome to the blog for Abtec, Inc.!

Check back frequently for news, updates, company announcements, and more!