In the manufacturing industry, two critical factors are involved: quickly getting the products to market and ensuring they are within the budget. The design for the manufacturing process specified by the product manufacturers is the most critical part that can substantially impact production outcomes. Therefore, it is more time and cost-efficient when injection molders are involved early in the design part of this process.

Injection molding is the manufacturing process of parts by injecting molten material into a mold. It can be performed with various materials; thermoplastic and thermosetting polymers are the most common.

Abtec Inc.’s top-of-the-line customizable solutions for plastic injection mold tooling can provide our clients with easy collaboration in every phase of the manufacturing process. By assisting you in working with information age technologies and advanced mold-making techniques, we can quickly produce precision injection molds efficiently and save your business on irrelevant or substandard prototyping.

During the design stage of the injection mold process, various aspects may directly impact the function of the finished product and the costs involved with its manufacturing. Here are some critical design considerations for better part moldability, appearance, and production efficiency. Read on!

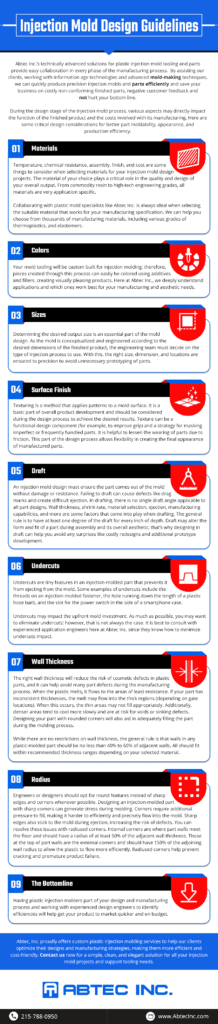

Materials

Temperature, chemical resistance, assembly, finish, and cost are some things to consider when selecting materials for your injection mold design projects. The material of your choice plays a critical role in the quality and design of your overall output. From commodity resin to high-tech engineering grades, all materials are very application specific.

Collaborating with plastic mold specialists like Abtec Inc. is always ideal when selecting the suitable material that works for your manufacturing specification. We can help you choose from thousands of manufacturing materials, including various grades of thermoplastics, and elastomers.

Colors

Your mold tooling will be custom built for injection molding; therefore, pieces created through this process can easily be colored using additives and fillers, creating visually pleasing products. Here at Abtec Inc., we deeply understand applications and which ones work best for your manufacturing and aesthetic needs.

Sizes

Determining the desired output size is an essential part of the mold design. As the mold is conceptualized and engineered according to the desired dimensions of the finished product, the engineering team must decide on the type of injection process to use and the venting requirements. With this, the right size, dimension, and locations are ensured to precision to avoid unnecessary prototyping of parts.

Surface Finish

Texturing is a method that applies patterns to a mold surface. It is a basic part of overall product development and should be considered during the design process to achieve the desired results. Texture can be a functional design component (for example, to improve grip) and a strategy for masking imperfect or frequently handled parts. It is helpful to lessen the wearing of parts due to friction. This part of the design process allows flexibility in creating the final appearance of manufactured parts.

From threaded inserts through ultrasonic welding or heat staking to pad printing and other methods, our team can help you decide on a surface finish that is best for your needs. We have a wide array of surface finishing options for molding that strengthen parts, improve cosmetic appearance, provide customization, and other benefits.

Draft

An injection mold design must ensure the part comes out of the mold without damage or resistance. Failing to draft can cause defects like drag marks and create difficult ejection. In drafting, there is no single draft angle applicable to all part designs. Wall thickness, shrink rate, material selection, ejection, manufacturing capabilities, and more are some factors that come into play when drafting. The general rule is to have at least one degree of the draft for every inch of depth. Draft may alter the form and fit of a part during assembly and its overall aesthetic; that’s why designing in draft can help you avoid any surprises like costly redesigns and additional prototype development.

Undercuts

Undercuts are tiny features in an injection-molded part that prevents it from ejecting from the mold. Some examples of undercuts include the threads on an injection-molded fastener, the hole running down the length of a plastic hose barb, and the slot for the power switch in the side of a smartphone case.

Undercuts may impact the upfront mold investment. As much as possible, you may want to eliminate undercuts; however, that is not always the case. It is best to consult with experienced application engineers here at Abtec Inc. since they know how to minimize undercuts impact.

Wall Thickness

The right wall thickness will reduce the risk of cosmetic defects in plastic parts, and it can help avoid many part defects during the manufacturing process. When the plastic melts, it flows to the areas of least resistance. If your part has inconsistent thicknesses, the melt may flow into the thick regions (depending on gate locations). When this occurs, the thin areas may not fill appropriately. Additionally, denser areas tend to cool more slowly and are at risk for voids or sinking defects. Designing your part with rounded corners will also aid in adequately filling the part during the molding process.

While there are no restrictions on wall thickness, the general rule is that walls in any plastic-molded part should be no less than 40% to 60% of adjacent walls. All should fit within recommended thickness ranges depending on your selected material.

Radius

Engineers or designers should opt for round features instead of sharp edges and corners whenever possible. Designing an injection-molded part with sharp corners can generate stress during molding. Corners require additional pressure to fill, making it harder to efficiently and precisely flow into the mold. Sharp edges also stick to the mold during ejection, increasing the risk of defects. You can resolve these issues with radiused corners. Internal corners are where part walls meet the floor and should have a radius of at least 50% of the adjacent wall thickness. Those at the top of part walls are the external corners and should have 150% of the adjoining wall radius to allow the plastic to flow more efficiently. Radiused corners help prevent cracking and premature product failure.

The Bottomline

Having plastic injection molders part of your design and manufacturing process and working with experienced design engineers to identify efficiencies will help get your product to market quicker and on budget.

Abtec, Inc. proudly offers custom plastic injection molding services to help our clients optimize their designs and manufacturing strategies, making them more efficient and cost-friendly. Contact us now for a simple, clean, and elegant solution for all your injection mold projects and support tooling needs.