- Cost Efficiency: Eliminating intermediaries often leads to cost savings. When you work directly with the manufacturer, you avoid paying commissions or fees to the middleman, making your tooling and parts more affordable.

Category: Services & Capabilities

Quick Turnaround Tooling Isn’t Always the Answer

Well-engineered, precision tooling is the key to quality molded parts. Quick turnaround tooling may get the job done fast and be affordable, but getting it done right is more important in industries that require precision. Investing in tooling services engineered to perfection ensures high-quality molded parts for your manufacturing requirements. Thus, you need state-of-the-art tooling services with an uncompromised commitment to quality and customer satisfaction.

Continue reading “Quick Turnaround Tooling Isn’t Always the Answer”

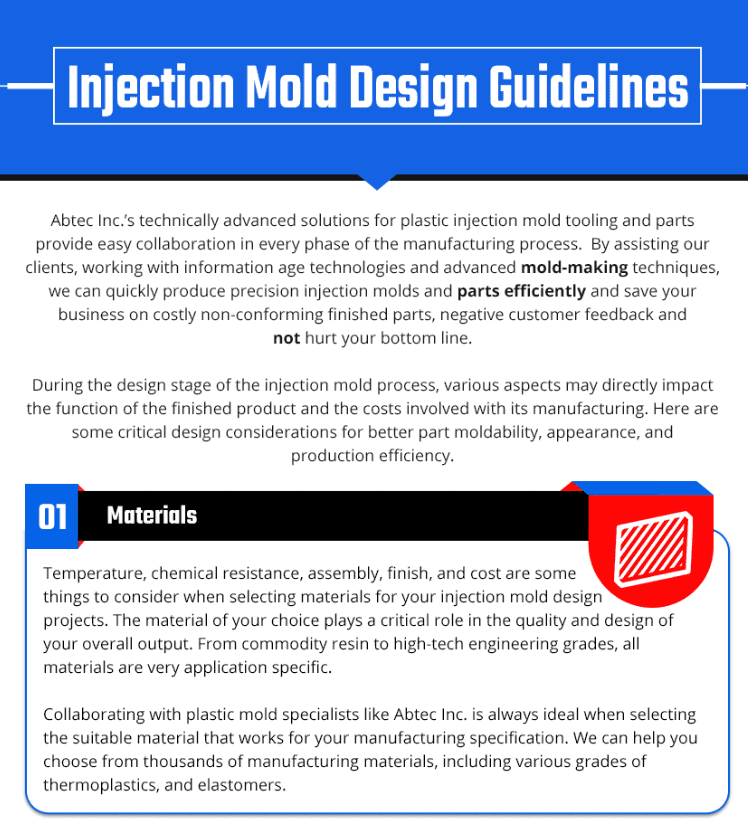

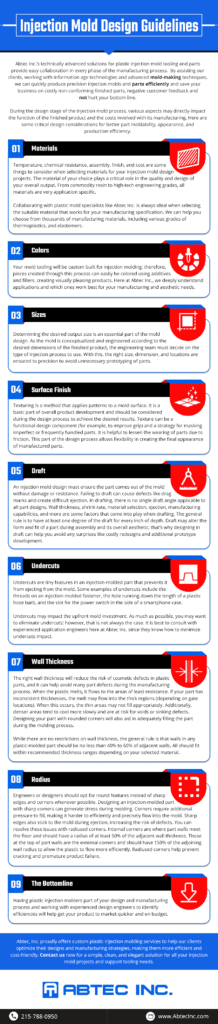

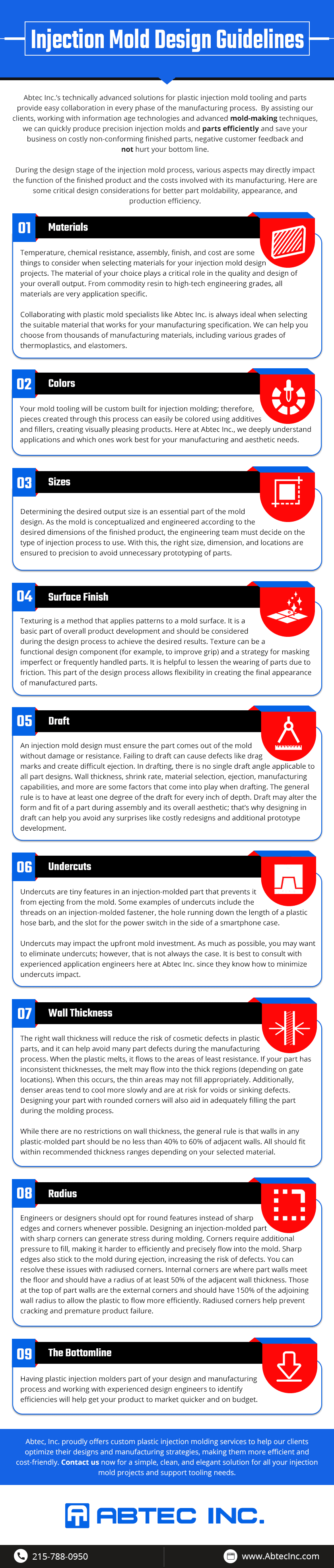

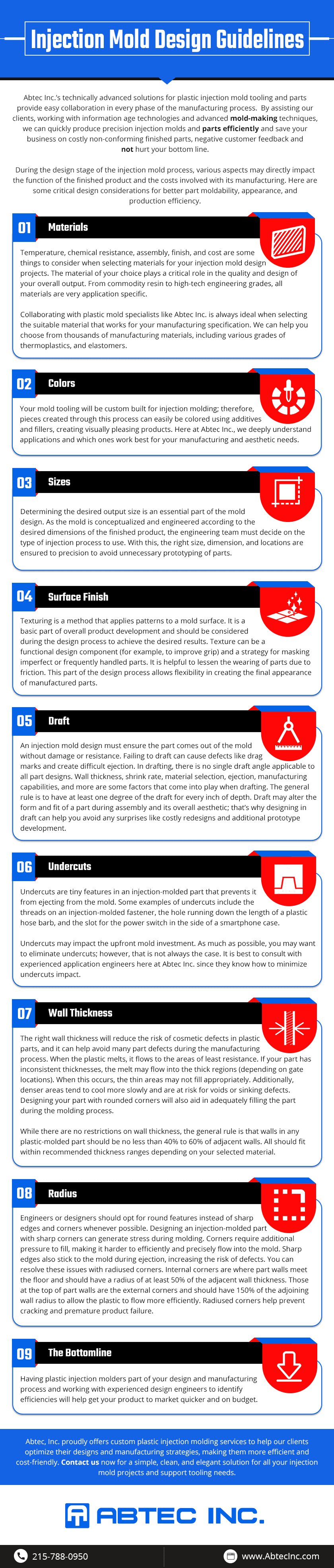

Injection Mold Design Guidelines

In the manufacturing industry, two critical factors are involved: quickly getting the products to market and ensuring they are within the budget. The design for the manufacturing process specified by the product manufacturers is the most critical part that can substantially impact production outcomes. Therefore, it is more time and cost-efficient when injection molders are involved early in the design part of this process.

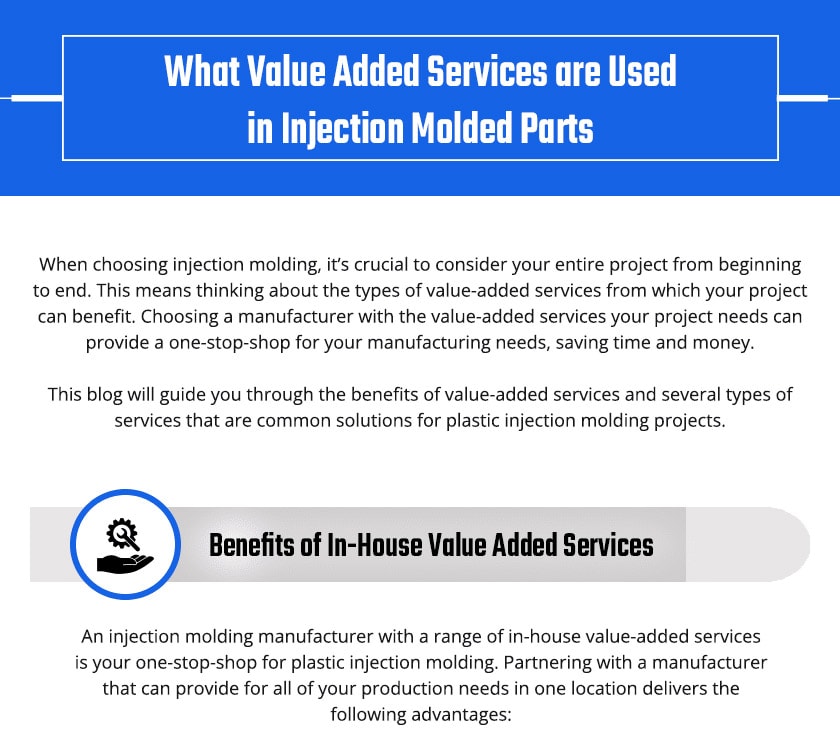

What Value-Added Services Are Used In Injection Molded Parts?

When choosing injection molding, it’s crucial to consider your entire project from beginning to end. This means thinking about the types of value-added services from which your project can benefit. Choosing a manufacturer with the value-added services your project needs can provide a one-stop-shop for your manufacturing needs, saving time and money.

Continue reading “What Value-Added Services Are Used In Injection Molded Parts?”

Proper Tooling & Injection Mold Maintenance at Abtec

Abtec has been providing custom injection molds and supporting tooling for various industries worldwide for more than 40 years. As a trusted global partner, we leverage cutting-edge technologies and advanced mold-making processes to produce precision injection molds within the shortest period of time. We also offer preventive mold maintenance solutions to guarantee the optimal performance of your molds and tools.

Continue reading “Proper Tooling & Injection Mold Maintenance at Abtec”

The Facts About Defense & Military Injection Molding

With more than a century of combined experience, Abtec Inc. provides quality plastic injection molding services to an array of industries. Our customers look to our parts to solve any number of production and manufacturing problems. They count on the versatility and efficiency of our equipment and team to fulfill a range of requests with quick turnaround times. Our expertise makes us well suited to deliver quality injection molded parts that meet the demanding standards of the defense and military sectors.

Continue reading “The Facts About Defense & Military Injection Molding”

Low-Volume or Short Run Injection Molding Solutions at Abtec

The process of bringing a new product to market involves many steps, including designing the component and creating prototypes to test out the design. After the design is finalized and the prototypes are evaluated, you may also want to produce a small number of pieces for internal or external product testing purposes before proceeding to full production. In the case of injection-molded components, one option for producing these pieces is short run injection molding—also known as small-volume, low-volume, or small-batch production. This production solution enables you to generate a limited batch that you can use to gauge market reaction so you can appropriately scale production to meet actual consumer demand.

Continue reading “Low-Volume or Short Run Injection Molding Solutions at Abtec”

Plastic Injection Molding for the Medical Industry

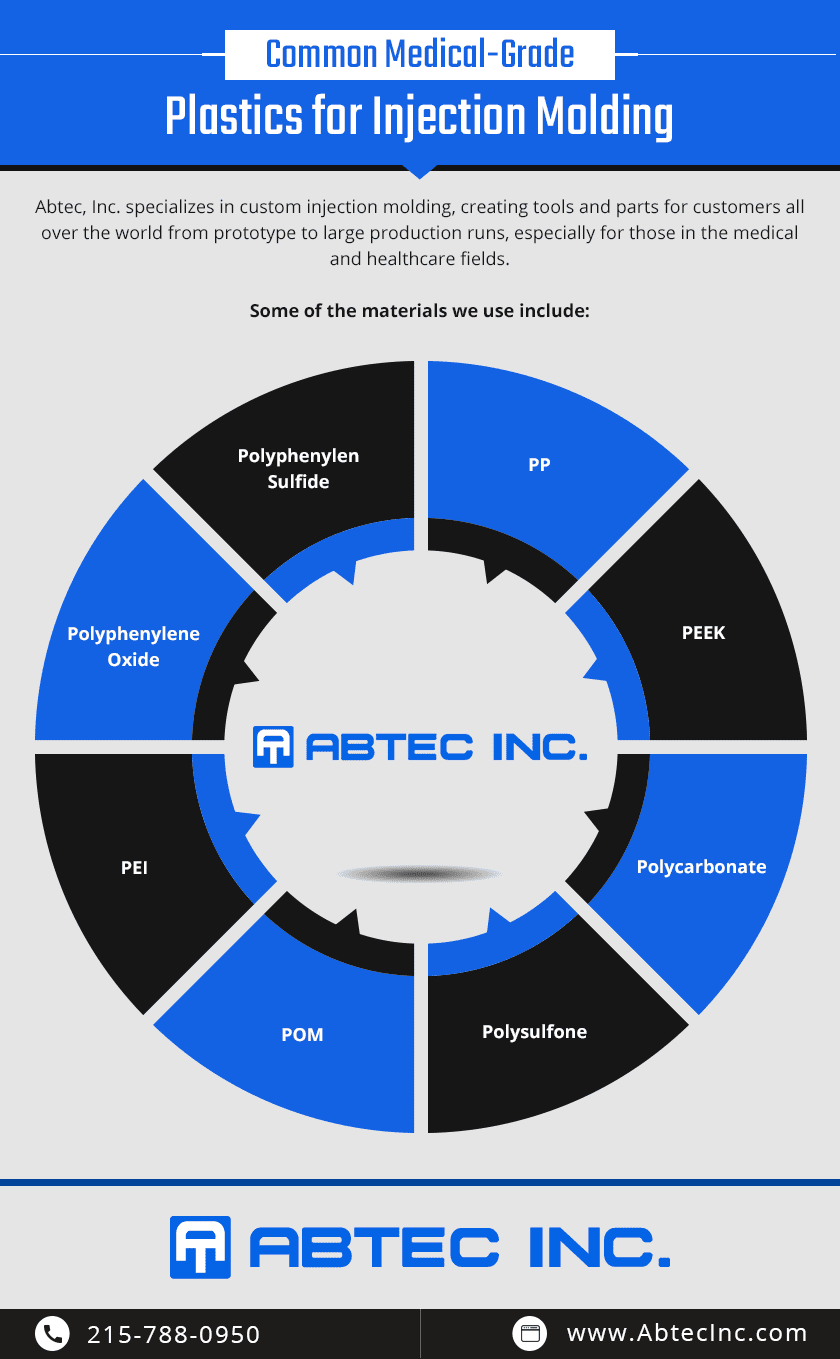

At Abtec, Inc., we specialize in custom injection molding, creating tools and parts for customers all over the world from prototype to large production runs. Plastic injection molding is a manufacturing process that involves injecting liquified plastic into a mold, allowing it to conform to the shape of the mold and harden to create a specific shape. This beneficial process has numerous applications in many industries, including the medical industry.

Continue reading “Plastic Injection Molding for the Medical Industry”

Is 3D Printing Better Than Injection Molding?

Advanced technology gives companies more options when it comes to producing plastic components. Plastic injection molding and 3D printing are two of those options, and they both have their advantages, depending upon the application. While 3D printing is relatively new and attention-grabbing, plastic injection molding is still a trusted solution for precision manufacturing.

Continue reading “Is 3D Printing Better Than Injection Molding?”

Custom Injection Molding Advantages at Abtec Inc.

At Abtec Inc., we’re proud to offer custom mold making services, helping clients bring their product visions to life. Versatile and reliable, plastic injection molding is used to create a huge range of everyday products. One of the most popular methods for mass producing plastic parts, this technique continues to rise in popularity across diverse industries and applications. Some of plastic injection molding advantages include the following:

Continue reading “Custom Injection Molding Advantages at Abtec Inc.”

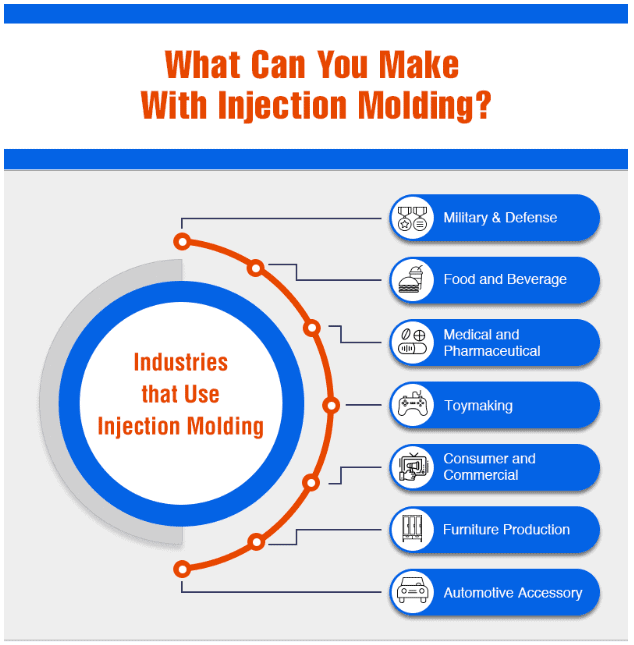

INFOGRAPHIC: What Can You Make with Injection Molding?

What can you make with injection molding? Scroll down to view our infographic!

Abtec, Inc provides injection molding services for a variety of materials and for a number of industries. Contact us today to find out how we can help with your next project!

Continue reading “INFOGRAPHIC: What Can You Make with Injection Molding?”

INFOGRAPHIC: The Advantages of Plastic Injection Molding

Abtec, Inc. offers injection molding services for custom molds based on your design. We have a broad catalog of materials and thermoplastics, plus years of expertise to help get the job done right!

Continue reading “INFOGRAPHIC: The Advantages of Plastic Injection Molding”

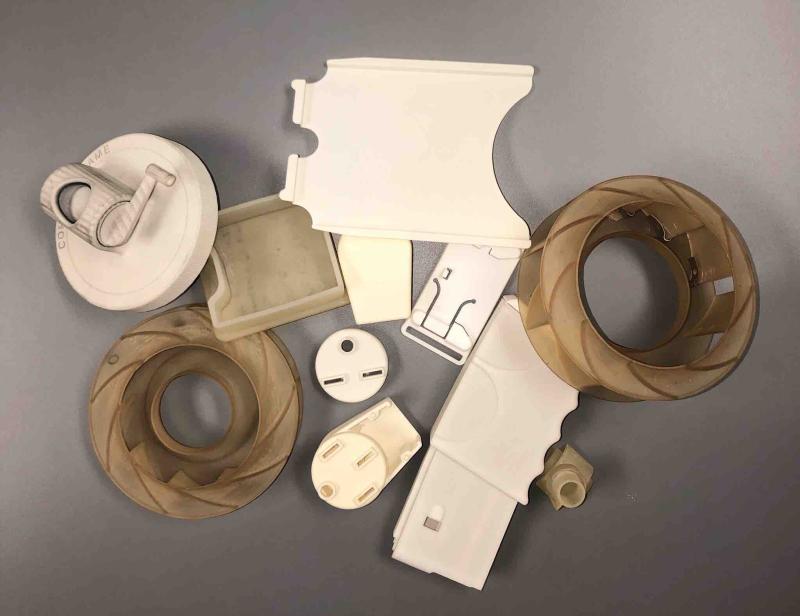

The Parts, Pieces, and Products Made From Custom Injection Molding

One of the biggest problems associated with creating or building materials is that sometimes, standard parts don’t fit your specific application. Sometimes, the tools you need to create these parts don’t even exist.

Continue reading “The Parts, Pieces, and Products Made From Custom Injection Molding”